MACHINES, PLANTS AND ENGINEERING |

|

|

|

|

for TECHNICAL DATA click here

|

LAKER realizes all types fo bucket excavators for the satisfaction of the varied

requirements of customers thanks to its great experience in this field. LAKER's first interest is that of reducing maintenance and for this reason it pays particular attention to wear parts such as driving groups, hydraulic and electric parts choosing among tha best mackes. LAKER produces high technology machines for the extraction of product both in open quarries and silos. These excavators find their application above all in the cement and brick industries. Their structure is very robust and guarantees both stability and a long life of all parts of the machine. |

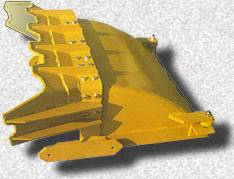

| Detail of a bucket made of steel. The profile of the teeh suits every kind of work. The back guide is guaranteed by sliding wheels. |  |

|

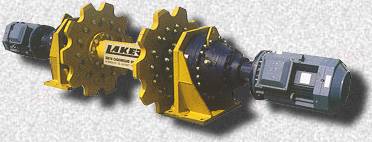

Detail of a complete driving group built with the most advanced technology. |

| Example of an installation of a bucket excavator type ECP: the sturdiness of the machine and also the device for the complete cleaning of the walls can be noted. |  |

|

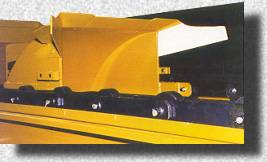

Detail of the bucket chain with watertight bearings on hardened and tempered bushes; these latter are lubrificated through a greaser inserted in the connection bolt; this system guarantees a long life. |

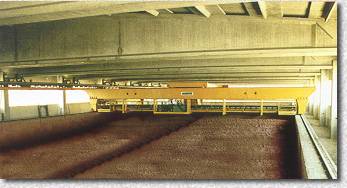

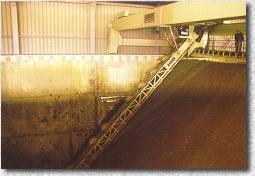

| Example of installation of a bucket excavator type ECS in a shed with open ends: The stability and the efficiency of the arm along its whole length (20 m) can be noted. |  |

|

Installation of excavator type ECS and side filling system with scattering conveyor belt. |

| Assembly of a huge excavator type ECS with airconditioned cabin and

energy generator with the suitable reservoir. This machine is in Belgium , weights 230 tons, has a 52-metre-long arm and a production capacity of 300 tons/per hour. Such a machine can, however, reach a production of 1000 tons/per hour. |

|

|

Detail of a filling of the silo with a LAKER-sitem. The PLC installed in the switchboard on board allows a lengthwise or transversal filling according to the choice of the customer. |

| One of the various installation of the excavator type ECP with filling trolley sliding on the same craneways. In this case the covering of the silo has not to support further weights and it is possible to save in the construction of the silo. LAKER, however, realizes every kind of filling system. |  |

|

High precision ultrasound probes guarantee a perfect distribution of the material. |

| One of the three machines - bucket excavators type ECS - installed in an important cement factory in the South of Italy; weight: 70 tons, arm length: 25 metres, production: 400 tons/per hour. |  |

|

Installation of a fifth wheel excavators type ECR in a cement factory: this machine can dig the material in 360°. |

| Installation of a bucket excavator type ECZ with the trolley sliding on the surface and hanging arm; this machine can dig not only but also in depth. The materials is unloaded on the belt. |  |

|

|

| Complete wiring of ecavators and filling systems in our factory. | |

|

All the machines are totally tested before delivery so that the assembly becomes quicker. |

|

|

| Moreover, the customer can plan with precision the shutdown of the plant avoiding production loss. | |

Web Site designed by MediaSoft® srl - © Copyright 1998-1999 - All rights reserved